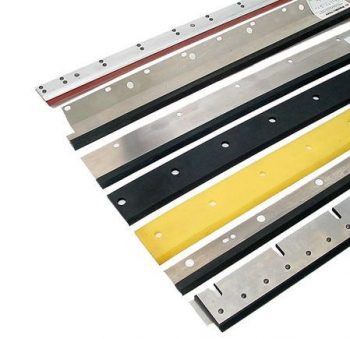

The wash-up blade is an important tool when cleaning the oscillating rollers in the offset printing unit before an upcoming ink change. The blade is responsible for scraping ink residues and cleaning agents from the rollers and out of the printing unit. The wash-up blades have a different appearance depending on the machine and installation environment.

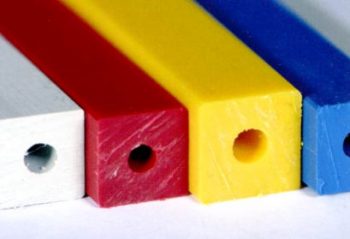

The conventional wash-up blades are made out of two parts: the basic steel blade with holes, cavities or a straight border needed for installing it into the holder and the rubber lip which lies against the roller.

You demand the highest performance from each part of the printing press. Lithosales stocks a large range of replacement wash-up blades which give excellent performance in all conditions. Together with strong chemical resistance to today’s aggressive inks and solvents, our blades have proven their high quality both to the original equipment manufacturer and to the end users.

Litho Sales & label Replacement Wash-Up Blades are the best:

• Manufactured to OEM specifications for ease of fitment.

• Quick wash-up performance.

• Specifically formulated rubber, plastic, and other specialty materials which ensure maximum performance and wear resistance.

• Distinctive bonding process between metal and rubber so that there is never a bond failure.

• Sharp and perfectly straight wiping edge.

• Specially treated metal for maximum corrosion resistance.

• Safe metal parts so that there are no sharp edges or burrs.

• Competitive pricing.